Products / Pressure Pipe & Fittings / Pressure Pipe Conduit / PVC Pressure Pipe Series 1 RRJ

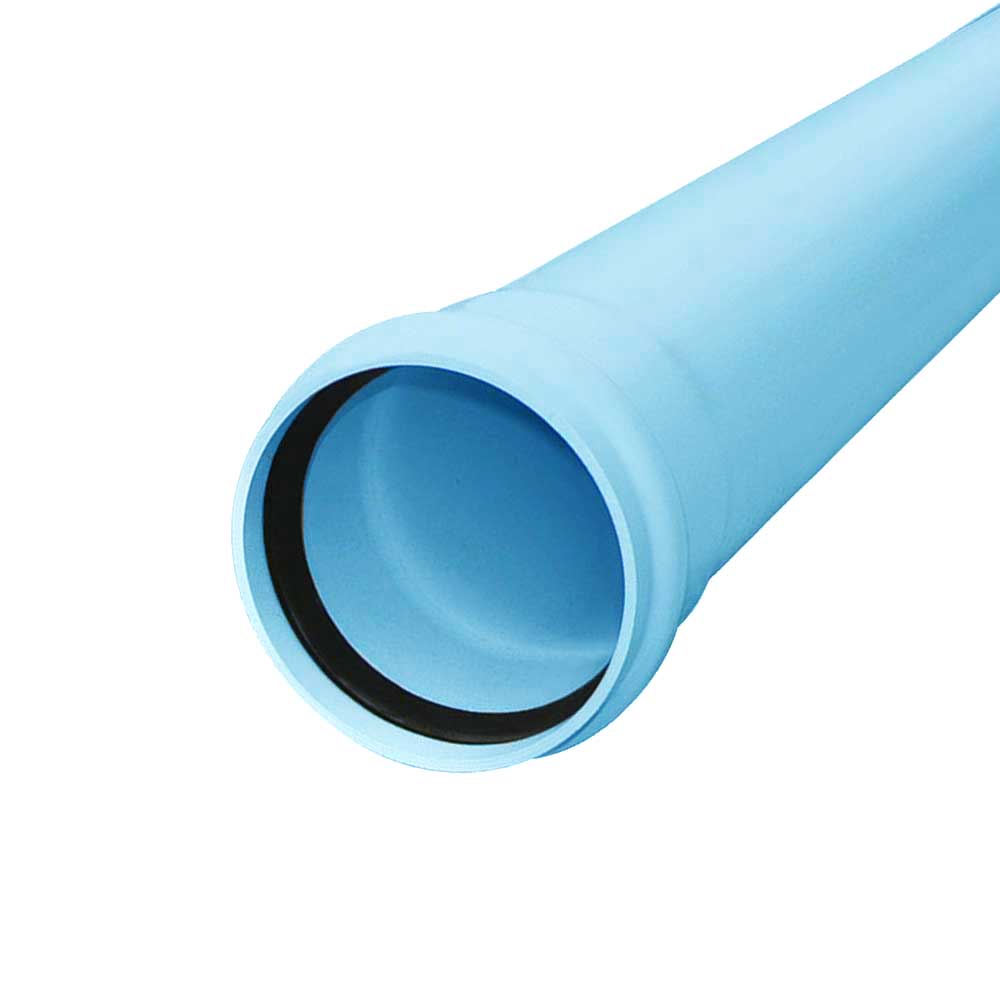

The PVC Pressure Pipe Series 1 RRJ (Rubber Ring Joint) is a high-performance pipe designed for various pressure applications. Its rubber ring joint (RRJ) provides a secure, leak-proof connection. Manufactured to AS/NZS 1477 standards, this pipe is ideal for potable water supply, drainage, sewer, irrigation, and watermains. Its robust PVC construction ensures long-lasting performance in both above-ground and underground installations.

With excellent chemical and corrosion resistance, the Series 1 RRJ pipe offers superior durability for residential, commercial, industrial, and municipal projects. It comes in 6-meter lengths and is available in purple for recycled water and cream for pressure sewer applications.

The PVC Pressure Pipe Series 1 RRJ is ideal for potable water supply systems. Its rubber ring joint provides a reliable, leak-proof connection, making it suitable for high-pressure applications while ensuring the safety of drinking water. Certified to AS/NZS 4020 standards, it complies with potable water use regulations.

Designed for both above-ground and below-ground installations, this pipe excels in sewer and drainage systems. Its corrosion resistance and chemical tolerance ensure long-term reliability in harsh environments, making it perfect for municipal sewer systems and drainage applications.

The PVC Pressure Pipe Series 1 RRJ is a great solution for irrigation systems, providing a durable and cost-effective option for large-scale agricultural projects. Its rubber ring joint allows for quick installation, making it ideal for both low and high-pressure applications.

A rubber ring joint (RRJ) uses a flexible rubber ring housed inside the pipe socket. When the spigot end of the pipe is inserted, the ring creates a watertight seal. This design eliminates the need for glue or solvent welding, simplifying installation. It also allows the system to maintain a secure seal while accommodating minor ground movement or temperature changes, ensuring long-term reliability in various environments.

PVC pressure pipes are categorized into two groups based on their external diameters: Series 1 and Series 2. Series 1 pipes feature internationally compatible (ISO) diameters, primarily measured in metric units, making them suitable for global standards. In contrast, Series 2 pipes have ductile iron-compatible diameters, designed for integration with older systems that used ductile iron piping. Both series are identified by their nominal size (DN), representing the pipe’s diameter, and their nominal working pressure (PN), which indicates the pressure they can withstand.

Different pipe colors denote their specific applications. Series 1 pipes used for potable water are typically white, while Series 2 pipes for drinking water are blue. Pipes used for recycled water are colored purple, and pressure sewer pipes are cream. Gas pipes are typically yellow.

PVC pressure pipes are supplied in straight lengths with spigot and socket ends and can be jointed using either Solvent Cement Jointing (SCJ) or Rubber Ring Jointing (RRJ), depending on the application.

The PVC Pressure Pipe Series 1 RRJ offers a reliable and cost-effective solution for water supply, drainage, sewer, and irrigation applications. Its strong rubber ring joint, corrosion-resistant design, and compliance with Australian standards make it an excellent choice for any project.

Contact Convic Australia today to find the right size, pressure rating, and configuration for your project, ensuring a secure and durable solution for your water, sewer, or drainage system.

Product Code |

Size |

Mean O.D. (mm) |

Mean I.D. (mm) |

Mean Wall (mm) |

Socket Length (mm) |

Weight (kg) |

Class (PN) |

Length (m) |

Bundle Quantity |

Pack Quantity |

| PRESS6-80RRJ | 80 | 88.9 | 83.7 | 2.6 | 120 | 6 | 6 | 6 | 1 | 104 |

| PRESS9-80RRJ | 80 | 88.9 | 81.3 | 3.8 | 120 | 9 | 9 | 6 | 1 | 104 |

| PRESS12-80RRJ | 80 | 88.9 | 79 | 5 | 120 | 11 | 12 | 6 | 1 | 104 |

| PRESS6-100RRJ | 100 | 114.3 | 107.8 | 3.3 | 140 | 10 | 6 | 6 | 1 | 60 |

| PRESS9-100MRRJ | 100 | 114.3 | 107.5 | 3.4 | 140 | 10 | 9 | 6 | 1 | 60 |

| PRESS12-100MRRJ | 100 | 114.3 | 105.6 | 4.4 | 140 | 13 | 12 | 6 | 1 | 60 |

| PRESS6-125RRJ | 125 | 140.2 | 132.2 | 4 | 150 | 15 | 6 | 6 | 1 | |

| PRESS9-125MRRJ | 125 | 140.2 | 131.9 | 4.2 | 150 | 15 | 9 | 6 | 1 | |

| PRESS12-125MRRJ | 125 | 140.2 | 129.5 | 5.4 | 150 | 19 | 12 | 6 | 1 | |

| PRESS6-150RRJ | 150 | 160.3 | 151.3 | 4.5 | 150 | 19 | 6 | 6 | 1 | 33 |

| PRESS9-150MRRJ | 150 | 160.3 | 150.9 | 4.7 | 150 | 20 | 9 | 6 | 1 | 33 |

| PRESS12-150MRRJ | 150 | 160.3 | 148.4 | 6 | 150 | 25 | 12 | 6 | 1 | 33 |

| PRESS6-175RRJ | 175 | 200.3 | 190.1 | 5.1 | 170 | 28 | 6 | 6 | 1 | |

| PRESS9-175MRRJ | 175 | 200.3 | 188.8 | 5.8 | 170 | 30 | 9 | 6 | 1 | |

| PRESS12-175MRRJ | 175 | 200.3 | 185.3 | 7.5 | 170 | 39 | 12 | 6 | 1 | |

| PRESS6-200RRJ | 200 | 225.3 | 213.8 | 5.8 | 190 | 35 | 6 | 6 | 1 | 12 |

| PRESS9-200MRRJ | 200 | 225.3 | 212.5 | 6.4 | 190 | 38 | 9 | 6 | 1 | 12 |

| PRESS12-200MRRJ | 200 | 225.3 | 208.6 | 8.4 | 190 | 49 | 12 | 6 | 1 | 12 |

| PRESS6-225RRJ | 225 | 250.4 | 237.7 | 6.4 | 200 | 43 | 6 | 6 | 1 | 12 |

| PRESS9-225MRRJ | 225 | 250.4 | 236.3 | 7.1 | 200 | 47 | 9 | 6 | 1 | 12 |

| PRESS12-225MRRJ | 225 | 250.4 | 232 | 9.2 | 200 | 60 | 12 | 6 | 1 | 12 |

| PRESS6-250RRJ | 250 | 280.4 | 266.2 | 7.1 | 200 | 54 | 6 | 6 | 1 | 11 |

| PRESS9-250MRRJ | 250 | 280.4 | 264.6 | 7.9 | 200 | 59 | 9 | 6 | 1 | 11 |

| PRESS12-250MRRJ | 250 | 280.4 | 259.9 | 10.3 | 200 | 75 | 12 | 6 | 1 | 11 |

| PRESS6-300RRJ | 300 | 315.5 | 299.5 | 8 | 210 | 68 | 6 | 6 | 1 | 6 |

| PRESS9-300MRRJ | 300 | 315.5 | 298 | 8.8 | 210 | 73 | 9 | 6 | 1 | 6 |

| PRESS12-300MRRJ | 300 | 315.5 | 292.4 | 11.6 | 210 | 96 | 12 | 6 | 1 | 6 |

| PRESS6-375RRJ | 375 | 400.5 | 380.3 | 10.1 | 230 | 110 | 6 | 6 | 1 | 6 |

| PRESS9-375MRRJ | 375 | 400.5 | 378.2 | 11.2 | 230 | 119 | 9 | 6 | 1 | 6 |

| PRESS12-375MRRJ | 375 | 400.5 | 371.4 | 14.6 | 230 | 153 | 12 | 6 | 1 | 6 |

| PRESS12-400RRJ | 400 | 450.5 | 406.4 | 22.1 | 250 | 265 | 12 | 6 | 1 | |

| PN6-450S1MR | 450 | 500.5 | 476.9 | 11.8 | 260 | 158 | 6 | 6 | 1 | 2 |

| PN9-450S1MR | 450 | 500.5 | 472.9 | 13.8 | 260 | 184 | 9 | 6 | 1 | 2 |

| PN12-450S1MR | 450 | 500.5 | 464.3 | 18.1 | 260 | 240 | 12 | 6 | 1 | 2 |

| PN6-500S1MR | 500 | 560.5 | 534.2 | 13.2 | 280 | 198 | 6 | 6 | 1 | |

| PN9-500S1MR | 500 | 560.5 | 529.6 | 15.5 | 280 | 232 | 9 | 6 | 1 | |

| PN12-500S1MR | 500 | 560.5 | 520 | 20.3 | 280 | 301 | 12 | 6 | 1 | |

| PN6-575S1MR | 575 | 630.5 | 601.1 | 14.7 | 320 | 247 | 6 | 5.9 | 1 | 2 |

| PN9-575S1MR | 575 | 630.5 | 596 | 17.3 | 320 | 289 | 9 | 5.9 | 1 | 2 |

| PN12-575S1MR | 575 | 630.5 | 585 | 22.8 | 320 | 377 | 12 | 5.9 | 1 | 2 |