Products / Plastic Poly Pits Lids & Risers / P1 to P9 Plastic Pit Range / P6, P8 & P9 Pits & Lids / Telstra Plastic Poly Pit P6

Introducing the Telstra approved Plastic Poly Pit P6, an underground utility access point designed for a wide range of applications, including telecommunications, electrical, air, rail, and road projects. These polymer pits are specifically engineered for use in various cabling and telecommunications applications, providing reliable underground access. Manufactured from black UV stabilized medium-density polyethylene (HDPE), the P6 Poly Pit offers exceptional strength, durability, and lightweight properties. With its robust construction and superior material composition, it ensures long-lasting performance and reliable functionality. Moreover, whether it’s for telecommunications networks, electrical installations, or transportation infrastructure, the Plastic Poly Pit P6 is the ideal choice for secure and efficient underground utility access.

Convic Australia, a trusted supplier, provides the high-quality P6 Poly Pit constructed from durable HDPE. Additionally, these pits exhibit superior resistance to moisture, chemicals, and impact. Through rotational moulding, the pits precisely crafted with consistent thickness and structural integrity, ensuring long-lasting performance. Our commitment to excellence in sourcing and supplying top-notch products guarantees reliability and longevity. Specifically designed for infrastructure projects, the P6 Poly Pit delivers dependable underground access for various applications.

Constructed from HDPE material, the P6 Poly Pit resists organisms and chemicals exceptionally well, minimizing the risk of environmental damage. Furthermore, its easy cutting capabilities provide a convenient solution for safe and straightforward ducting access. When installed correctly, this non-absorbent pit ensures watertightness, effectively protecting underground utilities. Additionally, the pit boasts excellent insulation properties, making it ideal for installations where electrical conductivity is a concern. Moreover, its unique side wall design provides the necessary structural integrity to withstand compaction loads from surrounding soil while supporting the required vertical loads. To enhance installation flexibility, the pits are equipped with built-in cutting guides, allowing installers to easily adjust the pit height for depth reduction or general installation purposes.

The lightweight HDPE material enables efficient transportation, storage, and handling, potentially reducing the carbon footprint. Moreover, the technically structured units minimize breakage and health and safety risks. Notably, the P6 Poly Pit is versatile, catering to landscape areas, sports fields, pavements, lighting pits, domestic environments, accidental trafficable locations, and CCTV installations.

Our pits can achieve Class B load rating under specific circumstances, ensuring adaptability to diverse installation conditions. Specifically, proper installation, backfilling with crushed rock or stabilized sand, and internal PVC pipe support enable the Telstra Plastic Poly Pit P6 to meet Class B load rating requirements. This flexibility allows you to tailor the pit’s load-bearing capacity to meet your project’s demands, ensuring optimal performance and safety.

Convic Australia offers a range of cover options, including concrete, composite, cast iron, and GMS covers, to suit specific needs. Importantly, these covers seamlessly integrate with the plastic pits, providing secure and reliable access points. With varying load ratings, they are suitable for different applications, ranging from Class A, Class B & Class C.

As a trusted supplier, Convic Australia provides high-quality polymer pits sourced from manufacturers approved and recognized by the major Australian Authorities in Telecommunications and Energy supply. With our extensive expertise and experience, we understand the importance of reliable underground access in infrastructure projects. Whether you require pits for telecommunications, electrical installations, air, rail, or road projects, Convic Australia offers the ideal choice with our P6 Pit. Contact us today for more information!

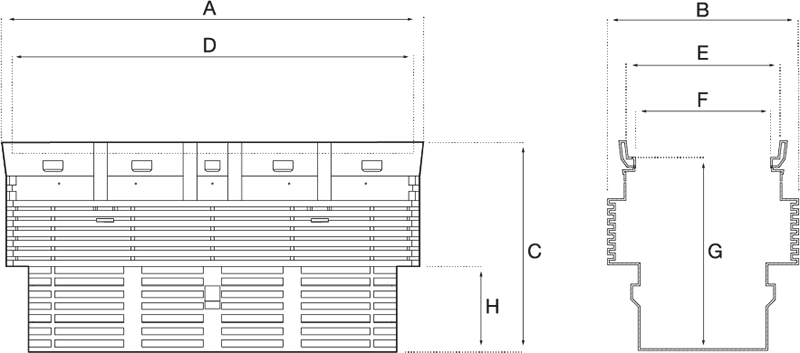

Weight (kg) |

Length (mm) |

Width (mm) |

Depth (mm) |

Clear Opening |

| 35 | 1375 | 615 | 685 | 1310 x 502 |

A |

B |

C |

D |

E |

F |

G |

H |

| 1375 | 615 | 685 | 1310 | 502 | 440 | 630 | 280 |

*All measurements in millimetres

| HDPE | |

| Compressive strength: | 58MPa D-695 |

| Flexural strength: | 15MPa D-790 |

| Tensile strength: | 14Mpa D638 |

| Water absorption: | +0.31% D-570 |

| Water vapour transmission: | WVT 0.1392g/m2 – 1,592hrs E96 |

| Coefficient of friction (Mannings): | n=0.010 |

| Chemical resistance | Good |

AS/NZ 3996

366/368 Settlement Road

Thomastown Vic 3074 Australia

Ph: (03) 9464 1655

sales@convicaustralia.com.au